How do metal composite conductive electrodes achieve a balance between high conductivity and high strength?

Release Time : 2025-10-29

As key functional components, conductive electrodes require not only excellent electrical conductivity for efficient energy transmission but also sufficient mechanical strength to withstand complex operating conditions such as thermal stress, vibration, and arc shock. However, while traditional pure metals offer excellent conductivity, they suffer from low strength and are prone to deformation and wear. High-strength metals or ceramics, on the other hand, often exhibit poor conductivity, making them difficult to meet electrical requirements. To overcome this performance bottleneck, metal composite conductive electrodes have emerged. Through scientific material design and process optimization, they have successfully achieved a synergistic combination of high conductivity and high strength, becoming a core material for high-end equipment.

1. Material Design: Multi-Phase Synergy, Complementary Advantages

Metal composite conductive electrodes are typically composed of a conductive matrix and a reinforcement phase. The conductive matrix provides continuous electron transport channels, ensuring low resistivity across the entire material. The reinforcement phase is evenly dispersed within the matrix, absorbing mechanical loads and improving hardness, tensile strength, and wear resistance. For example, in copper-carbon nanotube composite electrodes, the copper matrix ensures high conductivity, while the carbon nanotubes, as nanoscale reinforcements, significantly improve the material's strength and fatigue resistance, with minimal impact on conductivity.

2. Interface Optimization: Ensuring Efficient Electricity and Force Transfer

The key to composite material performance lies in the quality of the interfacial bonding between the matrix and the reinforcing phase. Poor interfacial bonding can lead to obstructed electron transport or stress concentration, affecting conductivity and strength. Therefore, surface modification techniques are often used to improve the wettability and bonding force between the reinforcing phase and the metal matrix. Furthermore, through in-situ synthesis or co-deposition processes, a transition layer can be generated on the surface of the reinforcing phase, forming a metallurgical bond, reducing interfacial defects, and achieving seamless transfer of current conduction and mechanical stress.

3. Structural Innovation: Gradient and Three-Dimensional Network Design

To avoid stress concentration caused by abrupt performance changes, some high-end electrodes employ a gradient structure design, that is, a gradual transition from a pure metal layer to a composite layer, allowing conductivity and strength to change continuously in space, improving overall reliability. Simultaneously, by employing 3D printing or foam metal skeleton filling technology, a three-dimensional conductive network is constructed, allowing the reinforcing phase to form a continuous skeleton with the metal matrix filling the spaces. This ensures efficient electron transport paths and endows the material with excellent compressive and impact resistance.

4. Advanced Fabrication Processes: Ensuring Performance Consistency

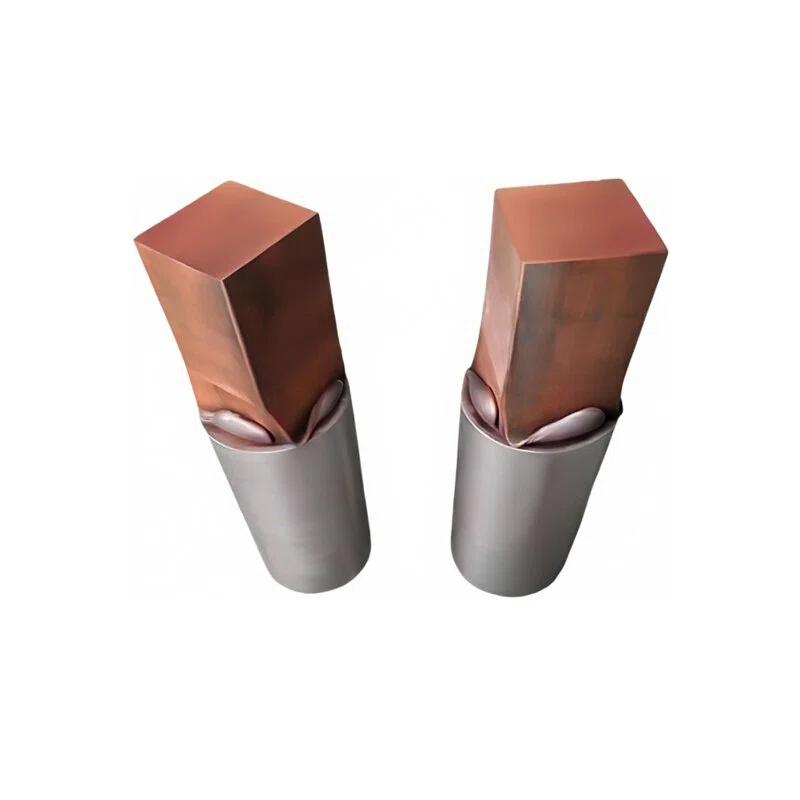

The fabrication process of metal composite materials directly affects their final properties. Commonly used methods include powder metallurgy, hot pressing sintering, explosive welding, electrodeposition, and friction stir welding. These processes can achieve densification under high temperature and pressure, reducing porosity and defects, and ensuring material uniformity and stability. For example, powder metallurgy can precisely control the composition distribution, making it suitable for fabricating high-strength, conductive electrodes such as copper-chromium and copper-tungsten electrodes, which are widely used in electrical contacts and electrode rods.

5. Thermal Stability and Fatigue Resistance

Under high current or high temperature conditions, pure metals are prone to softening, creep, or oxidation. The reinforcing phase in composite materials can effectively inhibit grain growth and dislocation movement, improving the material's recrystallization temperature and thermal stability. Simultaneously, its high strength properties can resist arc impact and thermal shock cracking, extending electrode lifespan.

In summary, metal composite conductive electrodes, through the synergistic effect of material composites, interface optimization, structural innovation, and advanced processes, have successfully broken the trade-off between conductivity and strength, achieving a dual breakthrough in performance. This is not only an outstanding achievement in materials science but also a key support for advancing high-end manufacturing and energy technologies.

1. Material Design: Multi-Phase Synergy, Complementary Advantages

Metal composite conductive electrodes are typically composed of a conductive matrix and a reinforcement phase. The conductive matrix provides continuous electron transport channels, ensuring low resistivity across the entire material. The reinforcement phase is evenly dispersed within the matrix, absorbing mechanical loads and improving hardness, tensile strength, and wear resistance. For example, in copper-carbon nanotube composite electrodes, the copper matrix ensures high conductivity, while the carbon nanotubes, as nanoscale reinforcements, significantly improve the material's strength and fatigue resistance, with minimal impact on conductivity.

2. Interface Optimization: Ensuring Efficient Electricity and Force Transfer

The key to composite material performance lies in the quality of the interfacial bonding between the matrix and the reinforcing phase. Poor interfacial bonding can lead to obstructed electron transport or stress concentration, affecting conductivity and strength. Therefore, surface modification techniques are often used to improve the wettability and bonding force between the reinforcing phase and the metal matrix. Furthermore, through in-situ synthesis or co-deposition processes, a transition layer can be generated on the surface of the reinforcing phase, forming a metallurgical bond, reducing interfacial defects, and achieving seamless transfer of current conduction and mechanical stress.

3. Structural Innovation: Gradient and Three-Dimensional Network Design

To avoid stress concentration caused by abrupt performance changes, some high-end electrodes employ a gradient structure design, that is, a gradual transition from a pure metal layer to a composite layer, allowing conductivity and strength to change continuously in space, improving overall reliability. Simultaneously, by employing 3D printing or foam metal skeleton filling technology, a three-dimensional conductive network is constructed, allowing the reinforcing phase to form a continuous skeleton with the metal matrix filling the spaces. This ensures efficient electron transport paths and endows the material with excellent compressive and impact resistance.

4. Advanced Fabrication Processes: Ensuring Performance Consistency

The fabrication process of metal composite materials directly affects their final properties. Commonly used methods include powder metallurgy, hot pressing sintering, explosive welding, electrodeposition, and friction stir welding. These processes can achieve densification under high temperature and pressure, reducing porosity and defects, and ensuring material uniformity and stability. For example, powder metallurgy can precisely control the composition distribution, making it suitable for fabricating high-strength, conductive electrodes such as copper-chromium and copper-tungsten electrodes, which are widely used in electrical contacts and electrode rods.

5. Thermal Stability and Fatigue Resistance

Under high current or high temperature conditions, pure metals are prone to softening, creep, or oxidation. The reinforcing phase in composite materials can effectively inhibit grain growth and dislocation movement, improving the material's recrystallization temperature and thermal stability. Simultaneously, its high strength properties can resist arc impact and thermal shock cracking, extending electrode lifespan.

In summary, metal composite conductive electrodes, through the synergistic effect of material composites, interface optimization, structural innovation, and advanced processes, have successfully broken the trade-off between conductivity and strength, achieving a dual breakthrough in performance. This is not only an outstanding achievement in materials science but also a key support for advancing high-end manufacturing and energy technologies.