What is the strength variation law of tungsten, a non-ferrous metal material, at high temperatures?

Release Time : 2025-11-14

Tungsten, a non-ferrous metal, plays a crucial role in high-temperature engineering due to its unique physicochemical properties. Its most significant characteristic is its extremely high melting point. As one of the metals with the highest melting point, tungsten maintains a solid structure even at extreme temperatures, making it an ideal material for manufacturing high-temperature components. In aerospace, tungsten alloys are widely used in rocket nozzles and gas turbine blades. These components need to operate for extended periods in environments with temperatures in the thousands of degrees Celsius, and tungsten's high melting point ensures structural integrity.

Regarding high-temperature strength, tungsten exhibits excellent creep resistance. When temperatures exceed 1000°C, ordinary non-ferrous metals show significant strength degradation, while tungsten maintains high tensile strength and hardness. This characteristic stems from its body-centered cubic crystal structure, which maintains relatively high resistance to dislocation movement at high temperatures. However, the high-temperature strength of tungsten does not change linearly; as the temperature rises to a certain range, its strength decreases in a stepwise manner, which is closely related to the recrystallization behavior within non-ferrous metals.

Tungsten undergoes significant microstructural evolution during high-temperature service. Tungsten materials prepared through plastic deformation processes undergo recovery, recrystallization, and grain growth under prolonged high-temperature conditions. In the initial rolled state, the grains are fibrous along the processing direction; as the high-temperature exposure time increases, the grains gradually transform into an equiaxed shape. This microstructural change leads to an increase in the ductile-brittle transition temperature and a decrease in plasticity and fracture toughness, directly affecting the service life and operational safety of non-ferrous metal materials.

Temperature has a significant impact on the recrystallization rate of tungsten. Experiments show that the higher the temperature and the greater the deformation, the faster the recrystallization process. For tungsten materials with low deformation, the effect of temperature on the recrystallization rate is more pronounced; however, as the deformation increases to a certain extent, the effect of temperature weakens. This nonlinear relationship requires precise control of temperature parameters and the degree of deformation in the heat treatment process design.

Regarding high-temperature oxidation resistance, tungsten exhibits a clear polarization characteristic. At room temperature, tungsten remains stable in air, but when the temperature rises to around 400℃, a dense, bluish-black tungsten trioxide protective film begins to form on the surface. However, when the temperature exceeds 500℃, especially in an aerobic environment, this protective film gradually fails, leading to a sharp decline in the performance of non-ferrous metal materials. Therefore, in practical applications, surface coating technology or inert gas protection is often required to improve their high-temperature oxidation resistance.

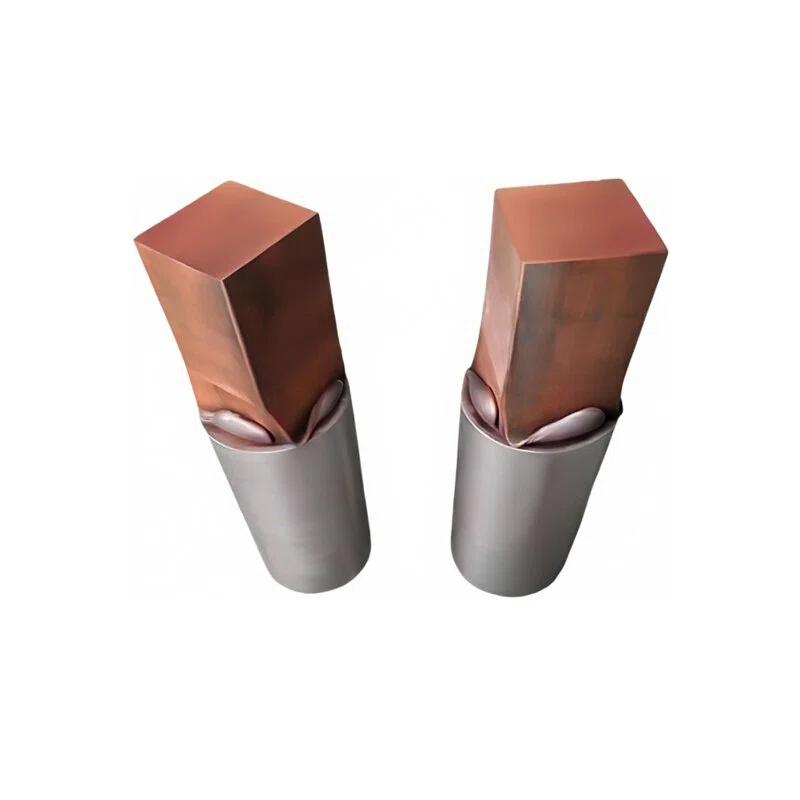

The high-temperature performance of tungsten alloys can be significantly improved through composition optimization. Tungsten-based alloys formed by adding binder metals such as nickel and iron significantly improve high-temperature ductility and impact resistance while maintaining high hardness. Sintering temperature has a decisive influence on the performance of these alloys. Within a specific temperature range, as the sintering temperature increases, the density, strength, and plasticity of the alloy all increase simultaneously; however, above the critical temperature, over-sintering leads to performance degradation.

Modern research techniques provide strong support for a deeper understanding of the high-temperature behavior of tungsten. Computer-aided simulation technology can accurately predict the changes in the mechanical properties of tungsten under dynamic high-temperature environments, and performance evaluation of non-ferrous metal materials can be completed by combining it with a small number of physical experiments. This research method not only reduces R&D costs, but also points the way for the development of new tungsten-based high-temperature non-ferrous metal materials, and promotes the continuous expansion of tungsten applications in cutting-edge fields such as nuclear fusion devices and aerospace.