How do metal composite conductive electrodes achieve high conductivity simultaneously through multiphase synergistic effects?

Release Time : 2025-12-02

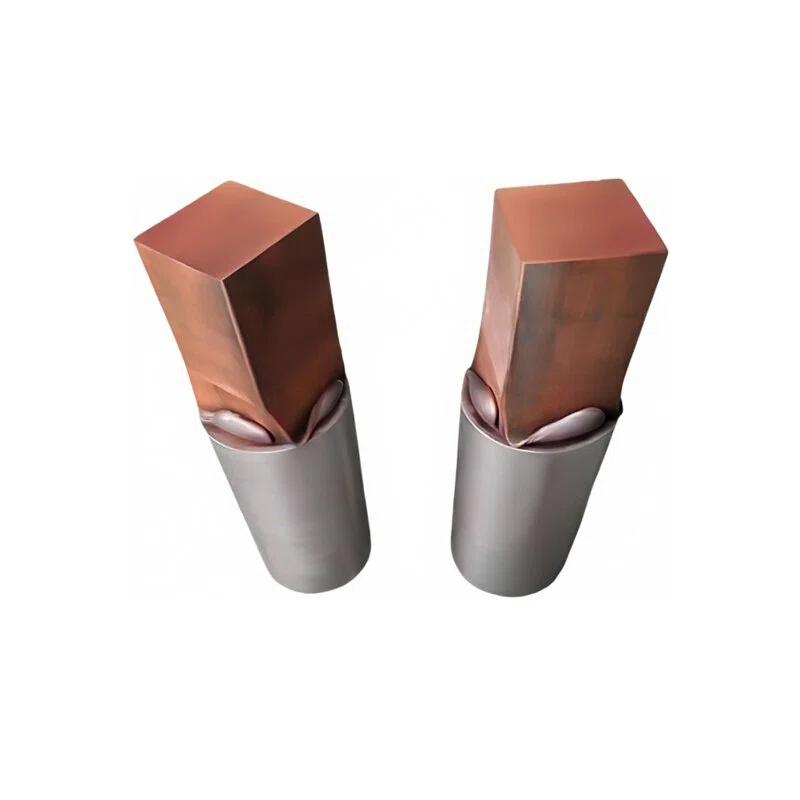

In modern electronics, energy, and high-end manufacturing, conductive electrodes not only need excellent conductivity to ensure efficient energy transfer, but also need to maintain structural integrity and long-term stability under complex operating conditions. While traditional pure metal electrodes exhibit excellent conductivity, they generally suffer from low strength, easy softening, poor creep resistance, and susceptibility to oxidation at high temperatures. Metal composite conductive electrodes, through cleverly designed multiphase structures, organically combine a conductive metal matrix with functional reinforcing phases. Utilizing the "multiphase synergistic effect," they successfully overcome the performance bottlenecks of single materials, achieving a balance of high conductivity, high strength, and high thermal stability.

1. Rational Matching of Conductive Matrix and Reinforcing Phase: The Basis of Functional Complementarity

Metal composite conductive electrodes typically use a highly conductive metal as a continuous matrix to ensure unobstructed electron transport channels; simultaneously, a second phase is introduced as a dispersed reinforcing agent. The key is that the reinforcing phase must possess high modulus, high melting point, and chemical inertness, and its volume fraction, size, and distribution must be precisely controlled—it must not excessively block electron pathways, while effectively hindering dislocation movement and grain boundary slip.

2. Interface Engineering Optimization: Reducing Contact Resistance and Improving Current Carrying Efficiency

The performance of multiphase systems is highly dependent on the quality of the interphase interfaces. If voids, oxide layers, or reaction products exist at the interface, they will form electron scattering centers, significantly increasing resistance. Therefore, advanced fabrication processes are used to construct clean, coherent, or semi-coherent interfaces. Some systems also improve wettability and inhibit harmful interphase reactions through surface modification or the addition of interfacial active elements. This precise interface control not only ensures the free migration of electrons in the matrix but also enables the reinforcing phase to effectively withstand mechanical stress without becoming a conductive "breakpoint."

Conductive electrodes often employ multi-scale composite strategies. For example, introducing nanoscale Al₂O₃ or TiC particles into a micron-sized copper matrix can simultaneously refine grain pinning dislocations; further composite with micron-sized silver fibers forms a "dual-conductivity network," further enhancing overall conductivity and fracture toughness. In addition, gradient structure design can optimize performance distribution in localized regions, meeting the functional requirements of different parts of the electrode. This multi-level structural synergy from nanoscale to macroscale is the core path to achieving integrated "strong-conductivity-stability."

4. Thermal-Mechanical-Electro-Coupling Stability: Reliable Guarantee for Harsh Operating Conditions

In high-current, high-frequency, or high-temperature environments, electrodes face multiple challenges such as Joule heat accumulation, thermal expansion mismatch, and electromigration. Metal composite materials, with their high thermal conductivity or low coefficient of thermal expansion of the reinforcing phase, effectively homogenize the temperature field, suppress thermal warpage, and delay structural degradation caused by atomic diffusion. For example, Cu/diamond composite electrodes not only achieve a conductivity exceeding 70% of pure copper, but also a thermal conductivity surpassing copper, while their coefficient of thermal expansion is closer to that of semiconductor materials, making them widely used in heat dissipation and interconnection of high-power devices.

In summary, metal composite conductive electrodes are not simply a mixture of metal and reinforcement, but rather a systematic engineering approach involving material selection, interface control, structural design, and process optimization to stimulate synergistic effects between different phases.

1. Rational Matching of Conductive Matrix and Reinforcing Phase: The Basis of Functional Complementarity

Metal composite conductive electrodes typically use a highly conductive metal as a continuous matrix to ensure unobstructed electron transport channels; simultaneously, a second phase is introduced as a dispersed reinforcing agent. The key is that the reinforcing phase must possess high modulus, high melting point, and chemical inertness, and its volume fraction, size, and distribution must be precisely controlled—it must not excessively block electron pathways, while effectively hindering dislocation movement and grain boundary slip.

2. Interface Engineering Optimization: Reducing Contact Resistance and Improving Current Carrying Efficiency

The performance of multiphase systems is highly dependent on the quality of the interphase interfaces. If voids, oxide layers, or reaction products exist at the interface, they will form electron scattering centers, significantly increasing resistance. Therefore, advanced fabrication processes are used to construct clean, coherent, or semi-coherent interfaces. Some systems also improve wettability and inhibit harmful interphase reactions through surface modification or the addition of interfacial active elements. This precise interface control not only ensures the free migration of electrons in the matrix but also enables the reinforcing phase to effectively withstand mechanical stress without becoming a conductive "breakpoint."

3. Multi-Scale Structural Design: Synergistically Enhancing Overall Performance

Conductive electrodes often employ multi-scale composite strategies. For example, introducing nanoscale Al₂O₃ or TiC particles into a micron-sized copper matrix can simultaneously refine grain pinning dislocations; further composite with micron-sized silver fibers forms a "dual-conductivity network," further enhancing overall conductivity and fracture toughness. In addition, gradient structure design can optimize performance distribution in localized regions, meeting the functional requirements of different parts of the electrode. This multi-level structural synergy from nanoscale to macroscale is the core path to achieving integrated "strong-conductivity-stability."

4. Thermal-Mechanical-Electro-Coupling Stability: Reliable Guarantee for Harsh Operating Conditions

In high-current, high-frequency, or high-temperature environments, electrodes face multiple challenges such as Joule heat accumulation, thermal expansion mismatch, and electromigration. Metal composite materials, with their high thermal conductivity or low coefficient of thermal expansion of the reinforcing phase, effectively homogenize the temperature field, suppress thermal warpage, and delay structural degradation caused by atomic diffusion. For example, Cu/diamond composite electrodes not only achieve a conductivity exceeding 70% of pure copper, but also a thermal conductivity surpassing copper, while their coefficient of thermal expansion is closer to that of semiconductor materials, making them widely used in heat dissipation and interconnection of high-power devices.

In summary, metal composite conductive electrodes are not simply a mixture of metal and reinforcement, but rather a systematic engineering approach involving material selection, interface control, structural design, and process optimization to stimulate synergistic effects between different phases.