Do conductive electrodes employ corrosion-resistant alloys or surface modification techniques?

Release Time : 2025-12-12

In electrochemical systems, energy conversion devices, and even industrial electrolysis equipment, conductive electrodes are not only current channels but also the interfaces where reactions occur. Their performance directly determines the efficiency, lifespan, and safety of the entire system. However, the working environments of electrodes are often extremely harsh—strong acids, strong alkalis, high-salt solutions, oxidizing media, or high-temperature and high-pressure conditions—all of which cause continuous corrosion to the materials. Therefore, whether corrosion-resistant alloys or advanced surface modification techniques are used has become a key criterion for evaluating the long-term stable operation of conductive electrodes.

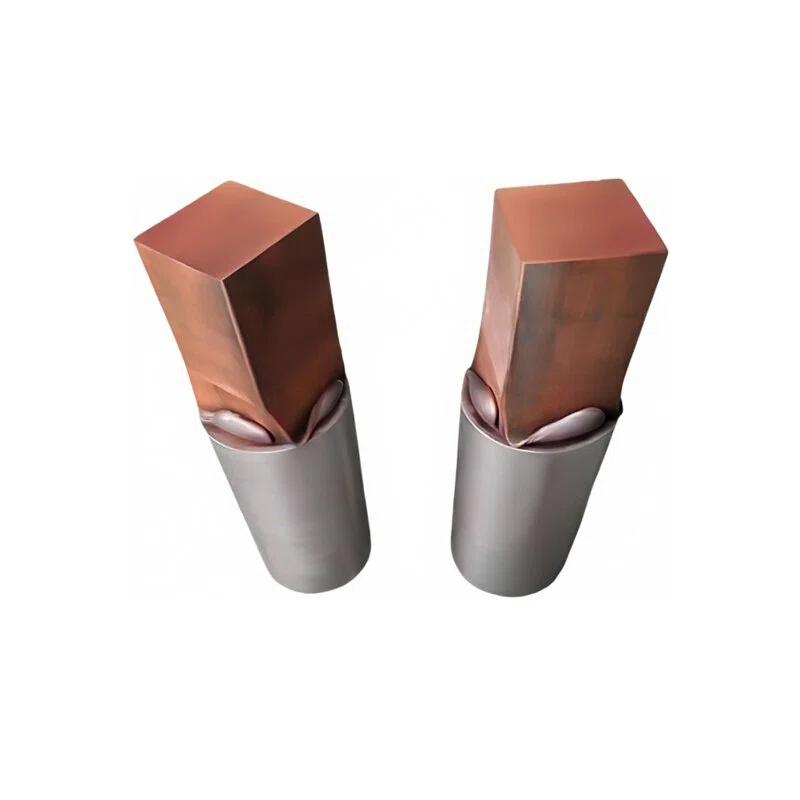

While traditional single-metal electrodes possess good conductivity, they are highly susceptible to oxidation, pitting corrosion, intergranular corrosion, or passivation film rupture in complex chemical environments, leading to increased resistance, decreased activity, and even structural collapse. Modern high-performance conductive electrodes, through a dual strategy of material composites and surface engineering, construct a robust "protective barrier." On the one hand, intrinsically corrosion-resistant metals such as titanium, nickel-based alloys, special stainless steels, or copper-chromium composite systems are selected as the matrix. These materials themselves can form a dense and stable passivation film in specific media, effectively preventing further corrosion. On the other hand, surface modification techniques can be used to construct functional protective layers on the electrode surface, achieving a "soft yet strong" protective effect.

Common surface modification methods include noble metal coatings (such as platinum, iridium, and ruthenium oxides). For example, coating a titanium substrate with a hybrid iridium-tantalum oxide coating not only significantly enhances the oxygen evolution reaction activity but also ensures the electrode remains stable for years in strongly acidic water electrolysis environments. Micro-arc oxidation can generate a ceramic-like oxide layer on aluminum or magnesium alloy surfaces, possessing both insulation and corrosion resistance, suitable for special electrochemical scenarios. Furthermore, processes such as laser cladding, physical vapor deposition (PVD), or electroless plating can also impart excellent corrosion resistance and synergistic catalytic properties to the electrode surface without significantly increasing weight.

This composite design concept of "substrate + functional layer" not only solves the corrosion problem but also achieves multifunctional integration. For example, the porous structure design increases the effective reaction area, the nanoscale coating improves charge transfer efficiency, and the gradient interface alleviates stress concentration caused by thermal expansion mismatch. Even under conditions of frequent start-stop cycles, current fluctuations, or sudden temperature changes, the electrodes maintain structural integrity and stable performance.

From an application perspective, corrosion resistance is directly related to system reliability. In the chlor-alkali industry, anode corrosion failure not only leads to soaring energy consumption but can also contaminate products. In fuel cells or flow batteries, electrode corrosion products can poison catalysts or clog flow channels. In cathodic protection systems in marine environments, electrode lifespan directly determines the protection cycle of the infrastructure. Therefore, adopting corrosion-resistant alloys or surface modification technologies is not simply an increase in cost, but a profound investment in the entire life cycle value.

Furthermore, this technology choice reflects a commitment to sustainable development. Long-life electrodes reduce replacement frequency, lowering resource consumption and waste generation; the use of non-toxic or low-toxic materials avoids the risk of secondary pollution. In today's increasingly important context of green energy and the circular economy, this has become a fundamental ethical principle for high-end electrode products.

In conclusion, whether conductive electrodes employ corrosion-resistant alloys or surface modification technologies reflects not only advancements in materials science but also a comprehensive consideration of safety, efficiency, and responsibility. It allows electricity to flow unimpeded even in the harshest environments and keeps chemical reactions precisely controllable over time—silently supporting the visible energy future at the unseen microscopic interface.

While traditional single-metal electrodes possess good conductivity, they are highly susceptible to oxidation, pitting corrosion, intergranular corrosion, or passivation film rupture in complex chemical environments, leading to increased resistance, decreased activity, and even structural collapse. Modern high-performance conductive electrodes, through a dual strategy of material composites and surface engineering, construct a robust "protective barrier." On the one hand, intrinsically corrosion-resistant metals such as titanium, nickel-based alloys, special stainless steels, or copper-chromium composite systems are selected as the matrix. These materials themselves can form a dense and stable passivation film in specific media, effectively preventing further corrosion. On the other hand, surface modification techniques can be used to construct functional protective layers on the electrode surface, achieving a "soft yet strong" protective effect.

Common surface modification methods include noble metal coatings (such as platinum, iridium, and ruthenium oxides). For example, coating a titanium substrate with a hybrid iridium-tantalum oxide coating not only significantly enhances the oxygen evolution reaction activity but also ensures the electrode remains stable for years in strongly acidic water electrolysis environments. Micro-arc oxidation can generate a ceramic-like oxide layer on aluminum or magnesium alloy surfaces, possessing both insulation and corrosion resistance, suitable for special electrochemical scenarios. Furthermore, processes such as laser cladding, physical vapor deposition (PVD), or electroless plating can also impart excellent corrosion resistance and synergistic catalytic properties to the electrode surface without significantly increasing weight.

This composite design concept of "substrate + functional layer" not only solves the corrosion problem but also achieves multifunctional integration. For example, the porous structure design increases the effective reaction area, the nanoscale coating improves charge transfer efficiency, and the gradient interface alleviates stress concentration caused by thermal expansion mismatch. Even under conditions of frequent start-stop cycles, current fluctuations, or sudden temperature changes, the electrodes maintain structural integrity and stable performance.

From an application perspective, corrosion resistance is directly related to system reliability. In the chlor-alkali industry, anode corrosion failure not only leads to soaring energy consumption but can also contaminate products. In fuel cells or flow batteries, electrode corrosion products can poison catalysts or clog flow channels. In cathodic protection systems in marine environments, electrode lifespan directly determines the protection cycle of the infrastructure. Therefore, adopting corrosion-resistant alloys or surface modification technologies is not simply an increase in cost, but a profound investment in the entire life cycle value.

Furthermore, this technology choice reflects a commitment to sustainable development. Long-life electrodes reduce replacement frequency, lowering resource consumption and waste generation; the use of non-toxic or low-toxic materials avoids the risk of secondary pollution. In today's increasingly important context of green energy and the circular economy, this has become a fundamental ethical principle for high-end electrode products.

In conclusion, whether conductive electrodes employ corrosion-resistant alloys or surface modification technologies reflects not only advancements in materials science but also a comprehensive consideration of safety, efficiency, and responsibility. It allows electricity to flow unimpeded even in the harshest environments and keeps chemical reactions precisely controllable over time—silently supporting the visible energy future at the unseen microscopic interface.