How can conductive electrodes achieve efficient energy transfer and long lifespan through metal composite material technology?

Release Time : 2025-12-26

In numerous industrial fields such as electrolysis, electroplating, battery manufacturing, electric arc furnace smelting, and new energy equipment, conductive electrodes serve as key interfaces for current input or output, and their performance directly determines system efficiency, operational stability, and maintenance cycles. Traditional single-metal electrodes often struggle to balance conductivity, mechanical strength, or corrosion resistance. However, novel conductive electrodes manufactured using metal composite material technology, through multi-layer or multi-phase structural designs, successfully integrate the advantages of different materials, becoming an irreplaceable functional core in demanding applications.

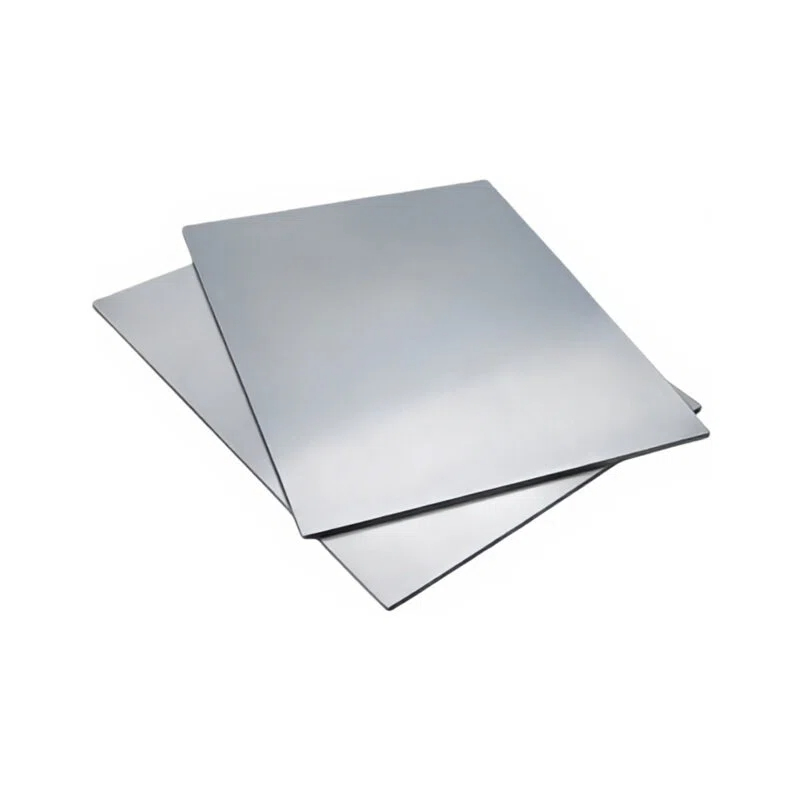

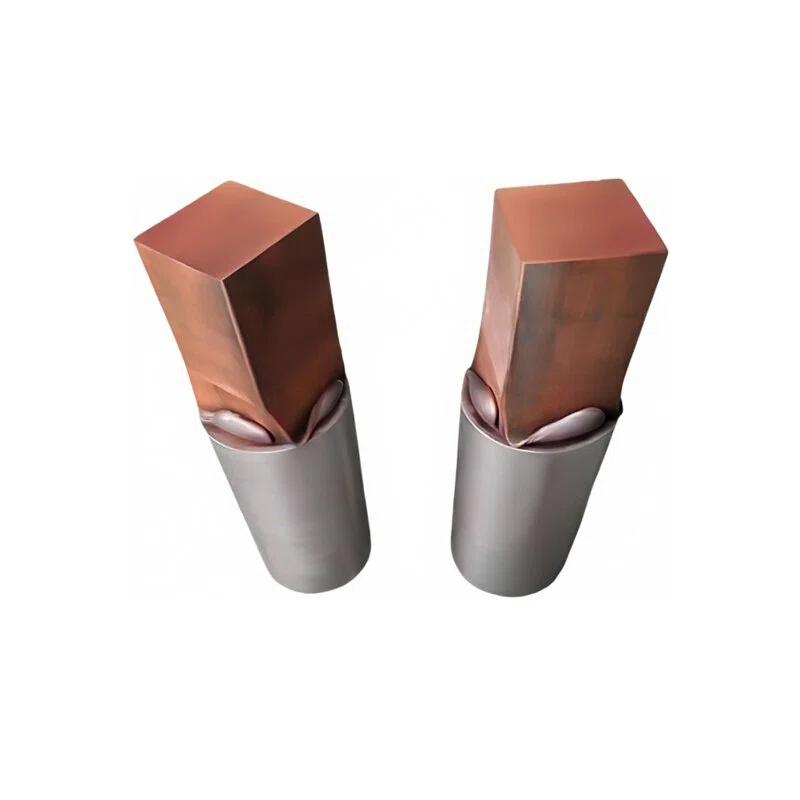

The core advantage of conductive electrodes stems from the synergistic effect of their composite material system. Typically, a highly conductive metal (such as copper, silver, or aluminum) is used as the matrix or core material to ensure low-resistance current transmission; the outer layer or working surface is coated with a high-hardness, corrosion-resistant, or catalytically active metal or alloy (such as titanium, tantalum, platinum group metals, or special stainless steel). This "internal conductive and external strong" structure not only ensures overall conductivity but also significantly improves surface stability in environments with strong acids, strong alkalis, high-temperature molten salts, or high current densities. Even when immersed in corrosive electrolytes for extended periods, the electrodes maintain their geometric integrity and electrochemical activity, preventing performance degradation or system contamination due to corrosion and spalling.

Excellent interfacial bonding strength is crucial for the reliability of composite electrodes. Advanced processes such as explosive welding, hot-rolled diffusion bonding, electrodeposition, or powder metallurgy create a robust metallurgical bond between different metal layers, rather than simple mechanical adhesion. This bond effectively resists differential expansion stress caused by thermal cycling, preventing delamination or cracking. Even under conditions of frequent start-stop cycles or severe load fluctuations, the electrode maintains structural continuity, ensuring uniform current distribution and preventing localized overheating or arc concentration.

In terms of functional customization, metal composite electrodes exhibit high flexibility. Material combinations can be adjusted according to specific application requirements: electrodes for the chlor-alkali industry can integrate ruthenium-iridium oxide coatings to improve chlorine evolution catalytic efficiency; electroplated anodes can employ titanium-based platinum-plated structures to achieve inert dissolution; and battery current collectors utilize copper-aluminum composite strips to balance lightweight design and conductivity. This "design-on-demand" capability transforms the electrode from a conductor into a smart interface with specific electrochemical functions.

Thermal management and mechanical support performance are equally outstanding. The high thermal conductivity core material rapidly conducts Joule heat to the cooling system, preventing hot spot accumulation; the reinforcing layer provides sufficient rigidity and creep resistance to support the deformation control of large electrodes under their own weight or fluid erosion. Some products also integrate cooling channels or mounting flanges, facilitating integration into complex equipment and improving overall engineering adaptability.

Furthermore, the life-cycle economics of composite electrodes are significantly better than traditional solutions. Although the initial cost is slightly higher, their ultra-long service life, maintenance-free characteristics, and high energy efficiency significantly reduce replacement frequency, downtime losses, and energy costs. In the context of increasingly stringent environmental regulations, their low metal leaching characteristics also reduce the burden of wastewater treatment, contributing to green production.

When current flows through the electrolytic cell, and when the electric arc burns stably in the furnace, the conductive electrodes, with their silent composite structure, bear the heavy responsibility of energy conversion. They are silent, yet make the reaction more efficient; unassuming, yet their precise multi-layered metal collaboration safeguards the system's stability. Because in the underlying logic of electrochemistry and electrical engineering, true performance breakthroughs often begin with carefully composited and scientifically designed conductive interfaces—and this is precisely the fundamental value of metal composite conductive electrodes in continuously leading high-end applications.

The core advantage of conductive electrodes stems from the synergistic effect of their composite material system. Typically, a highly conductive metal (such as copper, silver, or aluminum) is used as the matrix or core material to ensure low-resistance current transmission; the outer layer or working surface is coated with a high-hardness, corrosion-resistant, or catalytically active metal or alloy (such as titanium, tantalum, platinum group metals, or special stainless steel). This "internal conductive and external strong" structure not only ensures overall conductivity but also significantly improves surface stability in environments with strong acids, strong alkalis, high-temperature molten salts, or high current densities. Even when immersed in corrosive electrolytes for extended periods, the electrodes maintain their geometric integrity and electrochemical activity, preventing performance degradation or system contamination due to corrosion and spalling.

Excellent interfacial bonding strength is crucial for the reliability of composite electrodes. Advanced processes such as explosive welding, hot-rolled diffusion bonding, electrodeposition, or powder metallurgy create a robust metallurgical bond between different metal layers, rather than simple mechanical adhesion. This bond effectively resists differential expansion stress caused by thermal cycling, preventing delamination or cracking. Even under conditions of frequent start-stop cycles or severe load fluctuations, the electrode maintains structural continuity, ensuring uniform current distribution and preventing localized overheating or arc concentration.

In terms of functional customization, metal composite electrodes exhibit high flexibility. Material combinations can be adjusted according to specific application requirements: electrodes for the chlor-alkali industry can integrate ruthenium-iridium oxide coatings to improve chlorine evolution catalytic efficiency; electroplated anodes can employ titanium-based platinum-plated structures to achieve inert dissolution; and battery current collectors utilize copper-aluminum composite strips to balance lightweight design and conductivity. This "design-on-demand" capability transforms the electrode from a conductor into a smart interface with specific electrochemical functions.

Thermal management and mechanical support performance are equally outstanding. The high thermal conductivity core material rapidly conducts Joule heat to the cooling system, preventing hot spot accumulation; the reinforcing layer provides sufficient rigidity and creep resistance to support the deformation control of large electrodes under their own weight or fluid erosion. Some products also integrate cooling channels or mounting flanges, facilitating integration into complex equipment and improving overall engineering adaptability.

Furthermore, the life-cycle economics of composite electrodes are significantly better than traditional solutions. Although the initial cost is slightly higher, their ultra-long service life, maintenance-free characteristics, and high energy efficiency significantly reduce replacement frequency, downtime losses, and energy costs. In the context of increasingly stringent environmental regulations, their low metal leaching characteristics also reduce the burden of wastewater treatment, contributing to green production.

When current flows through the electrolytic cell, and when the electric arc burns stably in the furnace, the conductive electrodes, with their silent composite structure, bear the heavy responsibility of energy conversion. They are silent, yet make the reaction more efficient; unassuming, yet their precise multi-layered metal collaboration safeguards the system's stability. Because in the underlying logic of electrochemistry and electrical engineering, true performance breakthroughs often begin with carefully composited and scientifically designed conductive interfaces—and this is precisely the fundamental value of metal composite conductive electrodes in continuously leading high-end applications.