How to ensure the uniformity of properties across all parts of non-ferrous metal forgings during the forging process?

Release Time : 2026-01-05

Non-ferrous metal forgings are widely used in aerospace, rail transportation, energy equipment, and high-end electronics. Their performance uniformity directly affects the reliability and lifespan of the components. However, due to the low thermal conductivity, high deformation resistance sensitivity, and complex recrystallization behavior of non-ferrous metals, problems such as uneven microstructure, fluctuations in mechanical properties, and residual stress concentration easily occur during forging. Ensuring the consistency of properties across all parts of the forgings throughout the entire forging process becomes a core challenge in process design and quality control.

1. Rational Selection of Initial Billet and Pre-treatment Process

The foundation of performance uniformity begins with the raw materials. Ingots or extruded bars with uniform composition, no macroscopic segregation, and few internal defects should be selected as forging billets. For alloys prone to compositional segregation, homogenization annealing is necessary to eliminate dendritic segregation and improve microstructure uniformity. Simultaneously, the billet heating temperature and holding time must be strictly controlled: too low a temperature will lead to uneven deformation or even cracking; too high a temperature will cause abnormal grain growth or localized melting. Employing strategies such as gradient heating and segmented heat preservation can effectively reduce the temperature difference across the billet cross-section, laying a thermodynamic foundation for subsequent uniform deformation.

2. Optimizing Forging Process Parameters and Deformation Path

The degree of deformation, strain rate, and temperature are the three key variables affecting microstructure evolution. To avoid retaining the as-cast structure in localized areas due to insufficient deformation, or causing shear band concentration due to excessive deformation, a reasonable multi-pass forging scheme needs to be designed, ensuring a balanced distribution of reduction in each pass. For example, using an alternating upsetting-drawing process can break down coarse grains and promote dynamic recrystallization. For difficult-to-deform metals such as titanium alloys or magnesium alloys, isothermal forging or near-isothermal forging is preferable, ensuring the entire forging is formed at a constant high temperature, significantly improving flow uniformity. Furthermore, controlling the strain rate within the material's optimal hot working window helps obtain a fine and uniform recrystallized microstructure.

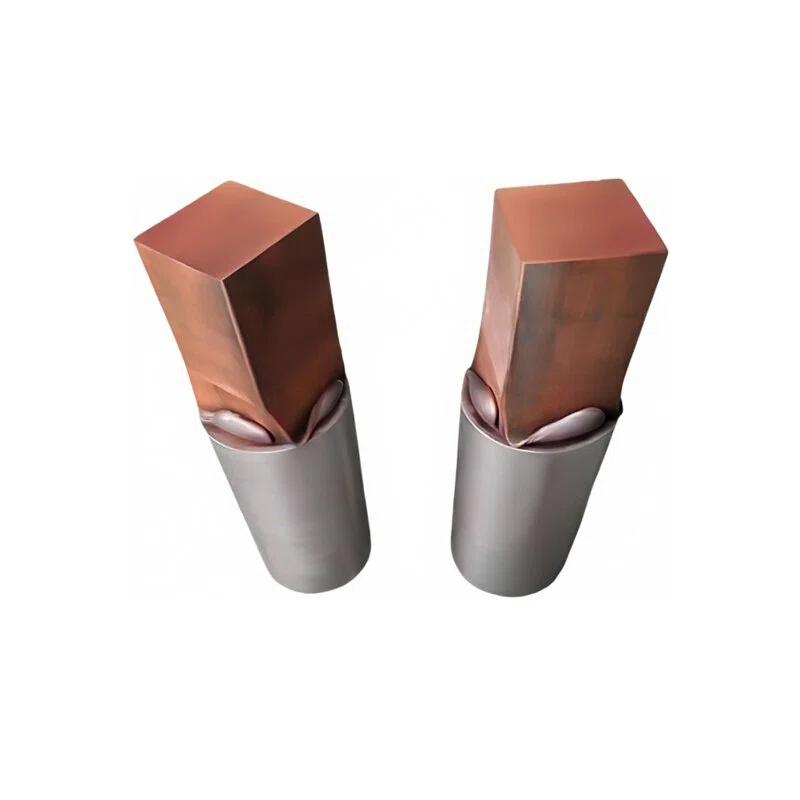

3. Scientifically Designing the Die Structure and Lubrication System

The die is not only a forming tool but also directly affects the metal flow pattern. Complex forgings often suffer from uneven metal flow due to geometric asymmetry, resulting in localized "dead zones" or overstretching. Finite element simulation can predict metal flow lines in advance, and based on this, optimize the die cavity fillets, draft angles, and flash groove layout to guide material to fill the cavity more evenly. Simultaneously, the use of high-performance lubricants not only reduces frictional resistance but also minimizes surface temperature drop, preventing the formation of a hard shell layer due to excessively rapid surface cooling. For high-temperature forging, the thermal stability of the lubricant must also be considered to prevent its decomposition and contamination of the forging surface.

4. Implementing Full-Process Temperature and Deformation Monitoring

Modern intelligent forging technology emphasizes a closed-loop "sensing-feedback-control" system. During the forging process, an infrared thermometer is used to monitor the surface temperature field of the billet in real time. Combined with thermocouples embedded in key locations to obtain internal temperature data, heating or pause times can be adjusted promptly. Strain sensors or visual tracking systems are simultaneously introduced to assess whether the actual deformation conforms to the preset path. Once excessive local temperature differences or abnormal flow are detected, the system can automatically adjust the press stroke or lubrication supply to achieve dynamic compensation and fundamentally suppress performance dispersion.

5. Strengthen Subsequent Heat Treatment and Quality Inspection

Even with good forging process control, slight differences in residual stress and microstructure may still exist. Therefore, appropriate heat treatment is necessary after forging to further homogenize the microstructure. Finally, performance sampling verification of different areas of the forgings is conducted through ultrasonic flaw detection, hardness grid testing, and metallographic sampling analysis to ensure that indicators such as strength, elongation, and grain size meet standard requirements.

In summary, ensuring the uniformity of performance in non-ferrous metal forgings is a systematic project that requires the integration of materials science, plastic forming theory, and intelligent manufacturing technology. Only through coordinated control of the entire chain, from billet preparation, process design, mold optimization to process monitoring and post-processing, can high-quality non-ferrous metal forgings with dense microstructure, consistent performance, and reliable durability be produced.

1. Rational Selection of Initial Billet and Pre-treatment Process

The foundation of performance uniformity begins with the raw materials. Ingots or extruded bars with uniform composition, no macroscopic segregation, and few internal defects should be selected as forging billets. For alloys prone to compositional segregation, homogenization annealing is necessary to eliminate dendritic segregation and improve microstructure uniformity. Simultaneously, the billet heating temperature and holding time must be strictly controlled: too low a temperature will lead to uneven deformation or even cracking; too high a temperature will cause abnormal grain growth or localized melting. Employing strategies such as gradient heating and segmented heat preservation can effectively reduce the temperature difference across the billet cross-section, laying a thermodynamic foundation for subsequent uniform deformation.

2. Optimizing Forging Process Parameters and Deformation Path

The degree of deformation, strain rate, and temperature are the three key variables affecting microstructure evolution. To avoid retaining the as-cast structure in localized areas due to insufficient deformation, or causing shear band concentration due to excessive deformation, a reasonable multi-pass forging scheme needs to be designed, ensuring a balanced distribution of reduction in each pass. For example, using an alternating upsetting-drawing process can break down coarse grains and promote dynamic recrystallization. For difficult-to-deform metals such as titanium alloys or magnesium alloys, isothermal forging or near-isothermal forging is preferable, ensuring the entire forging is formed at a constant high temperature, significantly improving flow uniformity. Furthermore, controlling the strain rate within the material's optimal hot working window helps obtain a fine and uniform recrystallized microstructure.

3. Scientifically Designing the Die Structure and Lubrication System

The die is not only a forming tool but also directly affects the metal flow pattern. Complex forgings often suffer from uneven metal flow due to geometric asymmetry, resulting in localized "dead zones" or overstretching. Finite element simulation can predict metal flow lines in advance, and based on this, optimize the die cavity fillets, draft angles, and flash groove layout to guide material to fill the cavity more evenly. Simultaneously, the use of high-performance lubricants not only reduces frictional resistance but also minimizes surface temperature drop, preventing the formation of a hard shell layer due to excessively rapid surface cooling. For high-temperature forging, the thermal stability of the lubricant must also be considered to prevent its decomposition and contamination of the forging surface.

4. Implementing Full-Process Temperature and Deformation Monitoring

Modern intelligent forging technology emphasizes a closed-loop "sensing-feedback-control" system. During the forging process, an infrared thermometer is used to monitor the surface temperature field of the billet in real time. Combined with thermocouples embedded in key locations to obtain internal temperature data, heating or pause times can be adjusted promptly. Strain sensors or visual tracking systems are simultaneously introduced to assess whether the actual deformation conforms to the preset path. Once excessive local temperature differences or abnormal flow are detected, the system can automatically adjust the press stroke or lubrication supply to achieve dynamic compensation and fundamentally suppress performance dispersion.

5. Strengthen Subsequent Heat Treatment and Quality Inspection

Even with good forging process control, slight differences in residual stress and microstructure may still exist. Therefore, appropriate heat treatment is necessary after forging to further homogenize the microstructure. Finally, performance sampling verification of different areas of the forgings is conducted through ultrasonic flaw detection, hardness grid testing, and metallographic sampling analysis to ensure that indicators such as strength, elongation, and grain size meet standard requirements.

In summary, ensuring the uniformity of performance in non-ferrous metal forgings is a systematic project that requires the integration of materials science, plastic forming theory, and intelligent manufacturing technology. Only through coordinated control of the entire chain, from billet preparation, process design, mold optimization to process monitoring and post-processing, can high-quality non-ferrous metal forgings with dense microstructure, consistent performance, and reliable durability be produced.